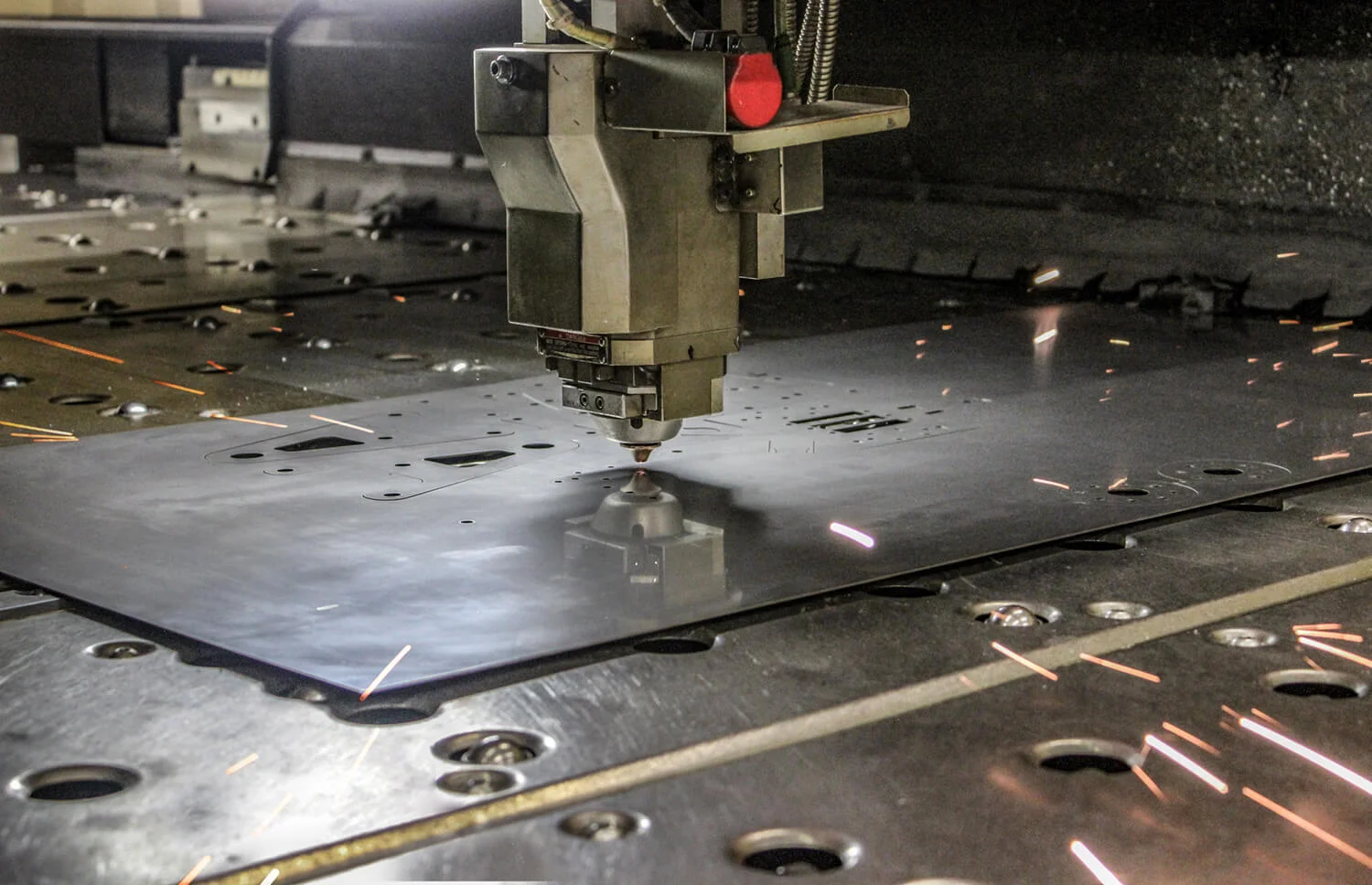

LASER CUTTING IS BEST USED WHEN THE GEOMETRY OF THE PART IS UNORTHODOX OR VERY COMPLEX IN NATURE

This equipment uses a laser beam to cut through a sheet of metal and “draw” the part’s geometry, resulting in a perfect replication of even the most complex looking parts. We will occasionally use a laser in conjunction with a punch press for those parts that have 3D properties in their shape, such as card guides or dimples, or if the piece has many holes or perforations in them. Our highly skilled laser operators are familiar with the coding language of the machines that they run, which allows us to reduce press time, and get your order through production faster than the competition.